Glulam Connections

There are a wide range of both ‘off the shelf’ and bespoke connectors, and structural joining solutions for joining different glulam elements together, like a column. The ones we recommend and typically adopt are detailed below.

Slotted Plate / Steel Dowelled Connections

We use this type of connection when the steelwork can be fitted in our workshops. Steel dowels are driven through the glulam into holes within the steel plates that are drilled at the same diameter as the dowels. This means that there is very little potential for movement within the joint.

The dowels are concealed with timber plugs so that no steelwork is visible. Dowels are often the best solution for highly loaded joints such as portal eave connections, where the large number of connections needed may look visually overpowering if they were left exposed.

Slotted Plate / Bolted Connections

This method is often best when structural loads are relatively high and the project is to be supplied as a kit of parts, to be assembled on site. We usually use large form ‘G’ washers and counterbore the fixings so they finish flush with the surface of the glulam.

Where steel feet or internal plate reinforcement (flitch plates) are specified, slots are cut out, holes drilled and counterbored to receive bolts, nuts and washers. This provides the same structural integrity as steel dowels but visually provides a much more contemporary industrial aesthetic.

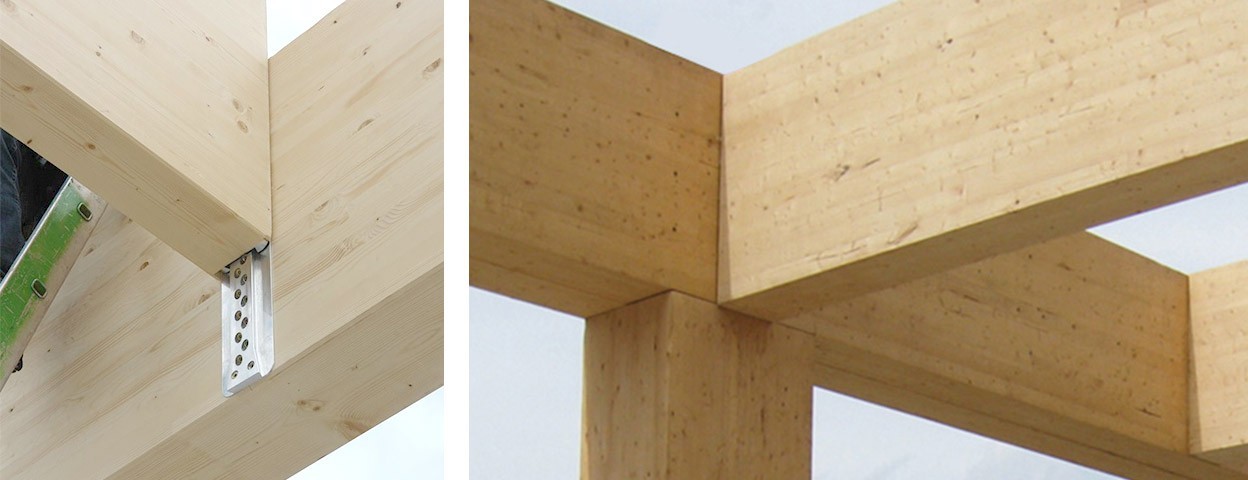

Concealed Beam Hangers

We use a range of ‘off the shelf’ concealed beam hangers. These are fitted directly onto the beams in the factory and allow for an easy ‘slot in’ fit on-site. When housed at the end of a beam they can be made invisible. If you desire no trace of fixings externally this is an ideal choice.

Resin Fixed / Anchor Joints and Bolts

These are another rapid and cost-effective method of jointing glulam. By adopting a resin anchor fixing system, no external traces are visible and the joining process is less labour intensive. These are best specified for joints that can be assembled in the factory under controlled conditions.

Screwed Connections

One connection option can be designed using large structural wood screws. This is a good, cost-effective and fast option for connections involving lower forces. Screwed connections can also be a good solution visually when there is a need to have no joist hangers or other steelwork visible.

Posts or beams can be counterbored, screwed into position and the holes plugged and sanded leaving very little external trace.

Joist Hangers

These are the most used and recognised method to join posts and rails. Where the structural timber work is not being left in an exposed state, these are a quick, cost effective and structurally robust method to support beams.

Bespoke Steelwork

Every commission is unique and always needs a range of bespoke elements. Where steel is concerned, we work with specialist engineering companies that fabricate our bespoke steelwork. Where needed we can powder coat, plate (galvanised and chrome) and even spray finish our steel elements as specified.

Contact Keith O Ceallaigh:

If you have any questions about a timber species or would like to visit our workshop and see some timber first hand contact Keith by email on keith@bucklandtimber.co.uk or by telephone on 01363 891 363.